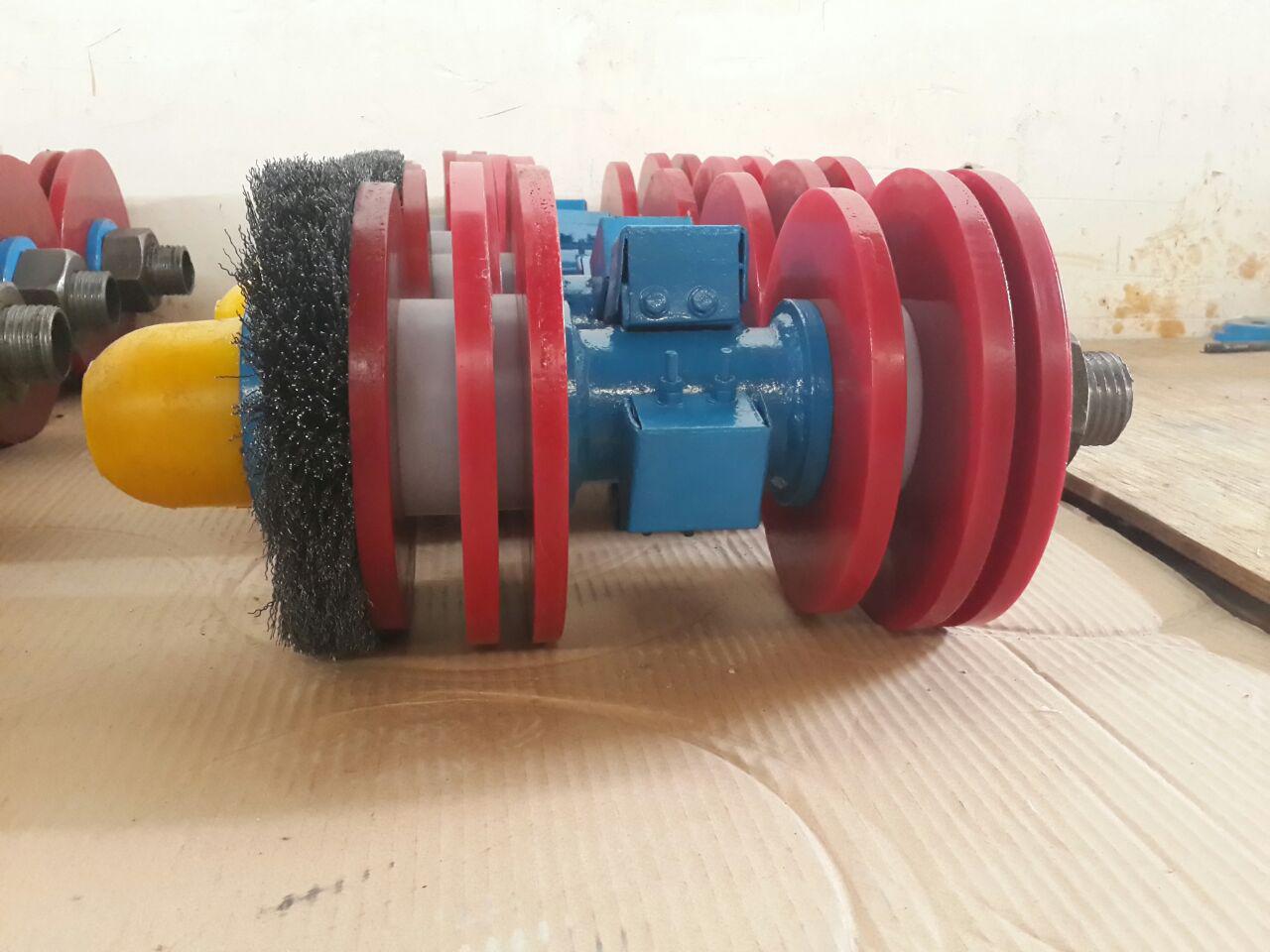

Bi-Direction Pig

This type of pig is designed and produced to separate two different fluids in pipelines from 4 to 56 inches. The double-sided pig is made of a metal body, and the seal and guide are made of polyurethane elastomers with high tensile strength and wear resistance. In double-sided pig, the weight of the pig is lighter. Because flood and guide replace all kinds of cups. This type of pig saves the time of testing and the amount of water consumed, and another advantage of this type of pig is the use of discs with a distance, which reduces the leakage coefficient and the possibility of reverse movement (reverse movement of the pig during the exit stages of the pig or Expelling a large volume of sediments is very useful and sometimes unavoidable in gas lines due to pressure fluctuations. This type of pig is for Filling & Dewatering operations. This type of pig is a combination of seal disc and guide disc, with the number of 2, 4 or 6 seal discs and a combination of brushes.

Applications

- It is used to empty pipelines of water in pressure (hydrostatic) testing.

- It is used to empty the fluid, to clean inside the pipelines.

- It is used to separate several dissimilar materials in multi-purpose pipelines.

- It is used to lower the line humidity in gas flows.

- These types of pigs cause more cleaning due to movement from both sides (two-way chasing).

- It is used to clean gaseous liquids and mud, sand and soot sediments from pipelines.

- It is used to pass 1.5D to 3D bend angles in pipelines.

Customization

- Installation of gauge plate made of aluminum or carbon steel to check pipes that are out of roundness or defects inside the pipe

- Installing Bypass and Plug to wash brushes

- Installation of magnets equipped with Flush system

- Installing the pig tracker plate to connect the pig tracker to the pig body

- Installing the wheel on the pig body

- Installation of rotating brush from size 4 to 56 inches made of Stainless Steel, Carbon Steel

- Installation of a base brush from size 16 to 56 inches made of Stainless Steel, Carbon Steel

- Installation of spring brush from size 16 to 56 inches made of Stainless Steel, Carbon Steel

- Increasing the number of spring brushes and base brushes according to the nominal size of the pipe

Features & Benefits

- According to the production planning, PolyTechs company has the possibility to deliver the requested pig in the shortest possible time.

- Polyurethane used is the best grade for pigs (cups, discs) which has high abrasion resistance and tensile strength. These polyurethane materials are used by reputable foreign pig makers.

- They have the ability to easily and quickly disassemble and assemble the pigs to replace the cups and discs.

- All the pigs produced by PolyTechs company have a warranty and technical support of the company.

- It is necessary to mention that PolyTechs company is concerned with producing a quality product that will gain the confidence of experts and respected consumers, taking into account the sensitivities and operational conditions and existing standards.

- The production method of polyurethane parts is machine and fully automatic.